The Printalyzer is a new project I've been working on for several weeks now. It aims to become a modern full-featured darkroom enlarger timer and exposure meter.

What is it?

At its core, this is a timer for a darkroom enlarger. That means it has a switchable outlet on the back, and can turn an enlarger on and off for a set amount of time. However, it is going to be far more sophisticated than a simple clock. Its going to allow the adjustment of exposure time in "stops," making it what is known as an "f-stop timer." That means you adjust time in logarithmic units of exposure, rather than linear increments. Here's an article that attempts to explain the concept.

Of course it'll also include features to help with making test strips, and calculating dodge/burn exposures in stop units as well.

In addition to all this, the device is going to include an exposure metering probe. This probe will let you measure and visualize the contrast range of a negative before printing it. The idea is that you can figure out a fairly decent choice of both contrast grade and exposure time, without even making a single test strip. Of course you still can make the strip, but it becomes more about fine-tuning than making your initial decisions.

Why are you doing it?

Why have I chosen to take on this project? Don't similar devices already exist? Well, technically they do. Several, in fact. You can find everything from polished commercial products to crowdfunding campaigns to homebrew hobbyist projects.

Okay then, why am I bothering?

Well, in short, I've found myself growing increasingly frustrated with what is currently out there.

Most of the commercial products in this space are quite expensive, and were designed and built in the mid-to-late 1990's. While they do work, they tend to suffer from all the limitations of "built to cost" embedded devices from that era. This often means a limited user interface that can be difficult to use without constantly referencing a manual, firmware that is difficult or impossible to update, features that are constrained by the capabilities of an 8-bit microcontroller, fixed peripheral choices, and a general lack of new development work.

Many of the more modern projects tend to forget things that made those old devices great, like a sturdy case, real buttons, and a no-nonsense primary interface. They also sometimes try to do too much, such as attempting to be a general purpose darkroom timer. Finally, its rare that they tackle the exposure metering problem.

What are your project goals?

Basically, to take what I like from those older products and to bring it up to date with more modern embedded technology.Fundamentally, I like to think of this project as building a platform, rather than a static appliance. Sure, its going to have all the necessary hardware to be an enlarger time and meter. However, its also going to have enough excess capacity so that it can be continuously updated to increase its functionality.

My goals for the Printalyzer include:

- Use real buttons for the user interface, and have enough of them that the need for awkward combinations is minimized. A rotary encoder knob may be used where it makes sense, but not as a catch-all.

- Use a graphical display whose layout can be changed depending on the device mode. It can emulate the look of 7-segment and bar-graph LEDs when that makes sense, but it can also display nice menus for setting things up.

- Use a flexible interface for connecting the metering probe, such that the choice of light sensor isn't baked into the device. It should be possible to use different sensors as desired, simply by plugging in a different probe. While I'll initially focus on B&W metering, being able to function as a color analyzer is absolutely a stretch goal.

- Have enough program memory that all desired features can be implemented. There should never be a reason to need different versions of the device to offer different feature sets.

- Have enough user memory that settings and calibration profiles are not arbitrarily limited, and can even be accompanied with meaningful descriptions.

- Include a USB port, so that settings can be saved/loaded from thumbdrives. It should also be possible to use this port to connect to other peripherals. This could include keyboards, for typing profile names, or even densitometers to automate the process of creating profiles.

- Include a "Blackout" switch that turns off all illumination on the device, enabling the user to perform basic functions by relying entirely on audio cues. This will be of great benefit when doing color printing, where paper must be handled in total darkness.

- Able to run off all common mains voltages, without modification (except maybe a different fuse).

- All hardware and software for the device will be completely open source, so that anyone can build or modify it.

My anti-goals, or things I explicitly do not plan to include:

- It will not be a multipurpose darkroom process timer. That means no timing of film development. This timer is meant to sit next to the enlarger, not to be carried around and used for everything.

- It will not require any sort of smartphone app or computer interface to set this thing up. It should be possible to use the device as a completely standalone unit, where all of its capabilities should be locally configurable.

How will it work?

The device will consist of a main unit that looks somewhat like every other enlarger timer, and a connected metering probe.

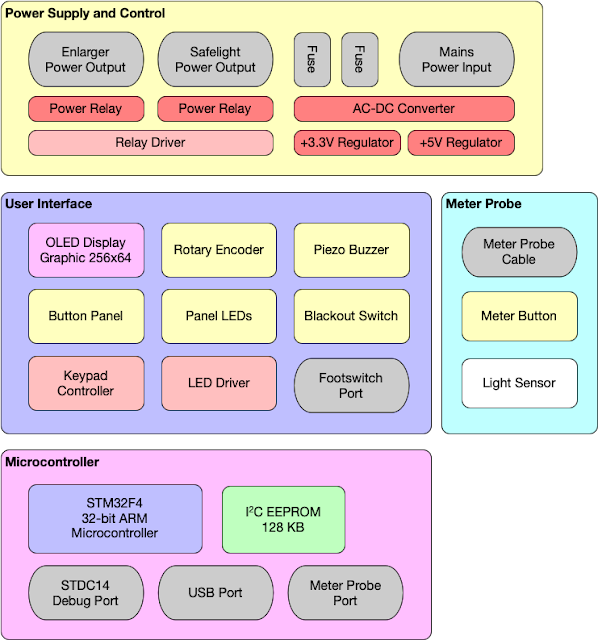

Here's a basic block diagram that shows the main components:

The main unit has buttons, a display, illumination LEDs, a buzzer, and relays to control both the enlarger and the safelights. The metering probe has a button, to trigger readings, and a light sensor.

How far along is the development?

The first revision of all the schematics and PCB layouts are finished. I've constructed the first prototypes of the metering probe, and am in the process of constructing the first prototype of the main unit. Once that is done, I'll have to do a lot of testing and begin to write the software. Since this is all open-source, you can see the nitty-gritty of this work on Github.

As far as the theory and process of print exposure adjustment and metering, I've also done a lot of research to prepare for the project. In addition to what I can figure out on my own, it also helps that there are a lot of long-expired patents that go into a good amount of relevant detail on the subject. Additionally, I'm hoping I can make the calibration profiles for this device compatible with other existing devices, to make initial setup as easy as possible.

Will I be able to get one?

That is the hope. While the first prototypes are mostly for me to be able to tinker around with an enlarger timer/meter that I can reprogram myself, I would eventually like to make this into a real product. I'm not yet sure if it'll be a DIY thing or a complete constructed unit. Its also likely that there will be non-trival legal, regulatory, and manufacturing hurdles to make this happen. I'll also need to get the cost down, as nice-looking prototype enclosures can be quite expensive.